Since last year, global inflation has had a strong impact on the business of shippers and carriers, who have seen their volumes decrease. Faced with the explosion of fuel prices and the shortage of drivers, which are having a lasting effect on the industry, parcel delivery companies are struggling to ensure their profitability. It has become necessary for them to reduce their costs and optimize their business. While some players are implementing a genuine cost reduction strategy, others are focusing on strategic investments to improve performance over the long term.

Learn how FedEx, UPS, GLS, DHL and GeoPost/DPDgroup are dealing with rising operational costs.

2022: A difficult year for the parcel delivery industry

Significant decline in volumes due to inflation

The year 2022 has been particularly challenging for logistics players: war in Ukraine, exploding fuel and energy prices… These latest events have led to a significant drop in parcel volumes for all parcel delivery players over the year 2022 :

- GLS: -1%

- DPDgroup: -1.3%

- DHL Express: -5.5% for international shipments and -14.1% for domestic shipments

- DHL Post & Parcel Germany: -8.3%

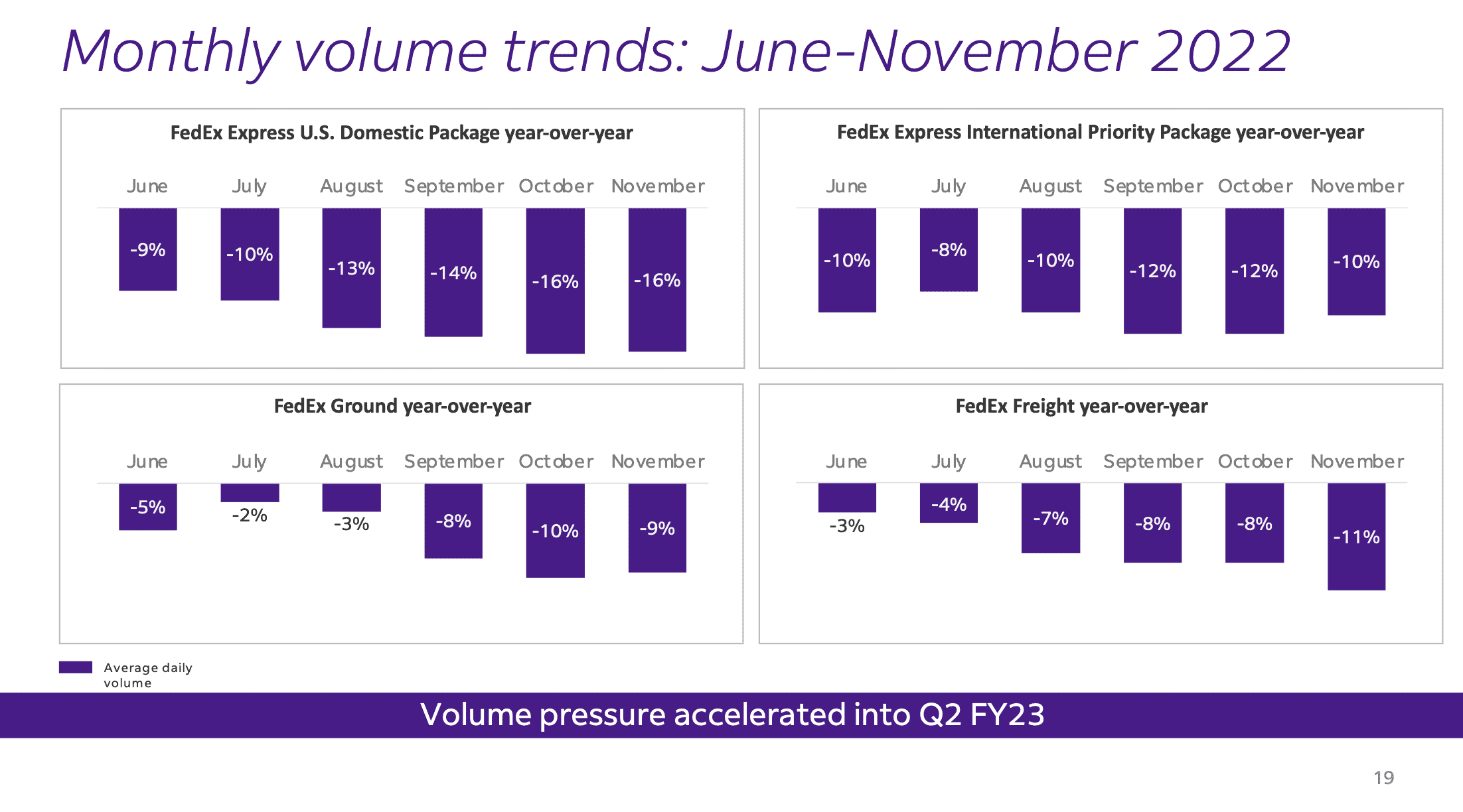

FedEx is also affected since, according to this graph taken from a presentation for its investors, all the group’s divisions have seen their volumes decline each month.

However, there are disparities between the groups’ subsidiaries, especially those that manage the last mile delivery business. For example, DHL’s Express division saw its profits fall (-4.6% in 2022), as did the eCommerce Solutions division (-6.7%) and Post & Parcel Germany (-27.2%).

For GLS, despite the increase in revenue, operating profit fell by 9.5%. As for Geopost, if the group has managed to increase its revenues by 5.9%, the explosion of operational costs is severely impacting profits, which are down by nearly 38.1%. This is reflected in the results of La Poste group, which announced -65% profits over the same period. And finally, for FedEx, the decline concerns both revenues (-5.9%) and profits (-21.8%).

Ambitious strategies to limit operating cost increases

Rate increases to keep up with inflation

To offset the increase in operating costs, all parcel delivery companies have announced a significant increase in the average price of their parcels in 2022 and 2023:

- FedEx: Rates for the Express, Ground and Home Delivery divisions will increase by an average of 6.9% and FedEx Freight by 6.9% to 7.9%.

- UPS: parcels also increased by an average of 6.9%.

- DHL: the Express division had already increased its rates by an average of 4.9% in 2021 and 5.9% in 2022. For 2023, the company has announced increases between 5.9% and 9.9% depending on the country.

- GLS: Since January 2023, GLS Canada has applied an average increase of 5.9%.

- DPDgroup has increased its rates for 2023 by introducing an energy surcharge, which consists of a surcharge for road transport (diesel and electricity) and another for air transport (kerosene). Recalculated once a month, the energy surcharge is based on the current market price of fuels and energy sources (electricity, gas) but also on their evolution. Depending on the country and the month, the surcharges range from 14% to 42%.

Major cost optimization programs for some parcel delivery companies

However, the rate increase will not be enough to improve carrier margins, which tend to be quite low already. Players are focusing on ambitious investment strategies and reorganizing their networks to achieve savings. This is notably the case for FedEx, which has unveiled a cost reduction program linked to its 2025 strategy “Deliver Today, Innovate for Tomorrow”. For fiscal year 2022-2023, the company has already sought to save $2.2 billion to $2.7 billion and expects to save an additional $4 billion each year across its existing network by 2025.

Among its various measures to reduce costs, FedEx plans to:

- Reduce flight frequencies and temporarily parking aircraft (FedEx Express).

- Reduce labor hours and and other linehaul expenses (FedEx Freight) based on volume.

- Consolidate some sorting operations to improve productivity.

- Reduce the number of Sunday deliveries at a number of FedEx Ground locations.

- Close approximately 150 FedEx Office and corporate offices.

- Defer hiring staff and avoid using suppliers.

- Cancel certain projects (including those to increase network capacity).

Then, by 2027, FedEx plans to save an additional $2 billion through its “Network 2.0” strategy, a network optimization with the elimination of 100 depots compared to today as well as more than 10% of all pickup and delivery routes. Indeed, the different depots of the network (FedEx Express, Ground and Freight) overlap in many areas, as can be seen on this slide from FedEx’s 2022 investor meeting presentation.

Operating a more efficient and profitable network is also a priority for UPS. The parcel delivery company has decided to limit the number of B2C e-commerce deliveries, which are generally less profitable routes because there are fewer parcels per stop. This change in strategy has particularly impacted Amazon, UPS’s largest customer. Revenues from Amazon deliveries now represent about 11% of UPS’s total revenues. With this strategy, UPS wants to expand into more profitable market segments such as small and medium-sized businesses and healthcare. At the same time, the company wants to consolidate deliveries in order to deliver more parcels per stop and thus make routes more efficient.

In response to declining volumes, UPS adjusted its network capacity to maintain profitable growth worldwide. For example, the U.S. company cancelled 75 flights out of China and shifted another 27 to European routes, allowing it to maintain a very high 98% load factor on flights outside Asia.

Ambitious investments for better performance over the long term

Parcel delivery companies are communicating more about their strategy to invest and optimize their existing network for better performance and profitability over the long term. This includes:

1. The acquisition of various strategic companies

This is notably the approach taken by GLS, which acquired Rosenau Transport, one of the largest independent freight carriers in Western Canada, in October 2021, as well as the start-up Tousfacteurs, which specializes in the development of digital and ecological solutions for parcel delivery, in June 2022.

2. The opening of new depots

In view of the strong growth of its business in recent years, DPDgroup is accelerating its investments to expand its network, increase its operational capacity and improve its performance by opening hubs:

- In September 2022, DPD BeLux (Belgium and Luxembourg) opened a €52 million international hub near Brussels to strengthen its position in Belgium and facilitate cross-border deliveries. The new 10,000m² depot can handle up to 20,000 parcels per hour.

- In the same month, DPD Ireland also opened a new 15,000m² distribution center in the southeast of the country, capable of handling nearly one million deliveries per year.

This is also the case for UPS, which opened a hub in Barcelona (Spain) and another in Bergamo (Italy) in 2022. The 24,000 square meter depot, located near the airport and port of Barcelona, can sort up to 22,000 parcels per hour, more than 2.5 times the capacity of the former depot.

For 2023, GLS Germany plans to open at least two new parcel distribution centers in the cities of Iggensbach (14,000 m²) and Potsdam (9,000 m²), which will become the largest depots operated by GLS in the country.

In 2022, DHL also relied heavily on new infrastructure, mostly based on the European and Asian continents: in the Netherlands (the new sorting center in Dordrecht can sort up to 200,000 parcels per day), Indonesia (Bekasi), Vietnam (Hanoi), Malaysia (Senai Airport City industrial zone), Belgium (Courcelles), France (Lesquin), Germany (Ludwigsfelde and Dortmund), and the United States (St. Petersburg).

3. Modernization and automation of the depots

In order to increase efficiency, parcel delivery companies are increasingly modernizing their infrastructures, in particular through accelerated automation of parcel sorting, which is being developed by GLS and DHL. In June 2022, GLS equipped its Hayward (California) center with an automated sorting system that can scan, weigh and measure up to 5,000 parcels per hour. Particularly focused on technological innovations and Artificial Intelligence, DHL wants to deploy 1,000 robots by 2025 in Asia-Pacific alone. This region of the world is also the field of experimentation for FedEx Express, which has implemented an AI-powered intelligent sorting robot in its South Pacific regional center in Singapore. This robotic arm is capable of sorting up to 1,000 parcels per hour, carrying up to 5kg on each trip and covering up to 100 destinations simultaneously.

In Estonia, DPD has, for example, implemented parcel delivery by Clevon autonomous robots with Euronics, the country’s largest electronics retailer. Following the success of this project, DPD has also tested these robots on public roads in the Netherlands where an operator can remotely control one robot (and up to 10 robots in the future). DPD Germany is also testing robots for sorting parcels at its Cologne-Porz depot with the company LoadRunners.

4. The deployment of digital tools

Digitalization is at the heart of DHL’s strategy: through 2025, the group will spend approximately €2 billion on initiatives to improve customer and employee experience and enhance operational excellence. These initiatives include:

- Modernization of the IT backbone in all business units: replace legacy applications for flexible state-of-the-art application portfolio.

- Creation of “Centers of Excellence” in which dedicated experts will help accelerating the adoption of new technologies and competencies.

Indeed, it is becoming essential for a group such as DHL to thoroughly modernize its IT systems and integrate new technologies for better performance such as the optimization of transaction processes, the continuous improvement of the network to reduce fuel consumption, warehouse automation, etc.

Data analysis is also central to improving the efficiency of the group’s operations: route optimization using advanced algorithms and operational volume prediction for optimized resource planning.

UPS is also moving toward technology initiatives to optimize its business with:

- the implementation of RFID tags on packages in 101 US sorting centers.

- traceability of a product’s life for better visibility from the manufacturer to the distribution points.

- an initiative to reduce late departures and deliveries, specifically targeting departures of hauling tractions carrying packages within the network.

How can Kardinal help parcel delivery companies optimize their operations to reduce costs?

For some parcel delivery companies, the challenge is to reduce the number of depots in order to mutualize the activity of several territories; for others it is, on the contrary, to open new ones. In the first case, this implies that the remaining depots will have to manage even more daily volumes; in the other case, the activity of the new depots is not yet optimal. It will therefore be essential for parcel delivery companies to optimize the operations of all their depots in order to improve their performance and reduce their costs.

Kardinal’s last mile delivery optimization platform is designed to improve operational performance from day one.

As a decision support tool, Kardinal’s solution enables last-mile transport depot managers to visualize and optimize their activity as well as to simulate development scenarios.

Based on the depot’s history and operational constraints (route, costs, resources, capacity, time, etc.), Kardinal’s algorithms define the optimal territorial sectorization and size the associated vehicle fleet as accurately as possible.

The territory of parcel delivery companies’ stations could therefore be optimized, especially between the various subcontractors who manage last-mile deliveries. Kardinal’s solution allows depot managers and their subcontractors to rely on precise and reliable data during their negotiations. Negotiations are no longer based on individual feelings and intuition.

With Kardinal’s optimization, all depot managers could each realize huge savings in operational costs, which cumulatively would significantly reduce the group’s expenses.

Kardinal’s solution also allows depot managers to optimize other issues related to last mile delivery:

- The implementation of a warehouse: measurement of the costs and the impact of a new agency or sub-depot on the sectorization of the territory.

- Anticipation of resources according to the evolution of the activity to avoid having to resort to emergency resources.

- Fleet change: calculation of costs and impact of new vehicles (electric vehicles, bicycles, trucks, etc.).

- Daily routes optimization according to the hazards on the field.

Do you think Kardinal’s solution would be relevant to your company’s cost reduction objectives? Contact us to discuss about it!